Links

Infiniti G37 Links

Sites of Interest

Recent Discussions

- Re: Part number for AC Amp for 2012 G37

- Re: Part number for AC Amp for 2012 G37

- Re: Part number for AC Amp for 2012 G37

- Re: Part number for AC Amp for 2012 G37

- Re: Part number for AC Amp for 2012 G37

- Re: 2007 G35 VQ35 (HR) Cranks but don't start

- Part number for AC Amp for 2012 G37

- 2007 G35 VQ35 (HR) Cranks but don't start

- Re: Dynamic Cruise Control on G37?

- Re: Dynamic Cruise Control on G37?

- G35 and G37 Engine, Drivetrain & Tuning • Re: U1000/U1001 after complete drivetrain and wiring swap

- G35 and G37 Engine, Drivetrain & Tuning • Re: U1000/U1001 after complete drivetrain and wiring swap

- G35 and G37 Engine, Drivetrain & Tuning • Re: U1000/U1001 after complete drivetrain and wiring swap

- G35 and G37 Engine, Drivetrain & Tuning • Re: U1000/U1001 after complete drivetrain and wiring swap

- G35 and G37 Engine, Drivetrain & Tuning • Re: U1000/U1001 after complete drivetrain and wiring swap

- G35 and G37 Engine, Drivetrain & Tuning • Re: U1000/U1001 after complete drivetrain and wiring swap

- G35 and G37 Engine, Drivetrain & Tuning • Re: U1000/U1001 after complete drivetrain and wiring swap

- G35 and G37 Engine, Drivetrain & Tuning • Re: U1000/U1001 after complete drivetrain and wiring swap

- G35 and G37 Engine, Drivetrain & Tuning • Re: U1000/U1001 after complete drivetrain and wiring swap

- G35 and G37 Engine, Drivetrain & Tuning • Re: U1000/U1001 after complete drivetrain and wiring swap

Of Interest

Wallpapers

G37 Sport edition Brake Pad Replacement

|

Parts needed: Parts were ordered as a kit via TunerzStore.com and include Project mu front pads and Hawk rear pads. Obviously you can use any brake pad available for the G37. Tools needed: Car jack, jack stands, 12mm wrench or socket, 22mm socket, rubber mallet, pick or small screwdriver. Optional: bucket/wire to hold caliper. |

||

|

Step 1. Open the hood and remove the panel indicated by the blue arrow. Under the panel you should see the brake fluid reservoir. You will need to remove some brake fluid prior to beginning this process. By whatever means necessary, remove an ounce or so of fluid and leave the cap off. As you perform the pad swap for each caliper you should monitor the fluid level to see if more brake fluid needs to be removed to avoid overflow.

Do the same steps above for the other side. |

|

|

Step 2. Start by jacking up the whole car, front or back of the car, or each corner as you work on them. When you remove a wheel make sure you put a couple of lug nuts back on to keep the rotor held in place (they are usually stuck anyway). |

|

|

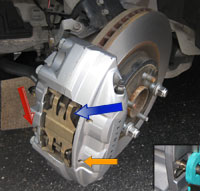

Step 3. Start by removing the locking clip from each of the two pins as indicated by the red arrow showing the lower pin (see indented picture for locking clip reference). Using a small screwdriver, push each pin (orange arrow location) until you can grab the inner head and remove. Once both pins are removed the metal Cross Spring can be removed and set aside.

Note: The picture referenced has the top pin already removed and the bottom pin pushed in to the point it can be removed. The locking clips have already been removed. After removing the pins use some light sand paper and clean the old grime off them. |

|

|

Step 4. Remove both old brake pads. They should slide straight out from the caliper. Once out remove the metal shims that are attached to the back of the factory pads and clean the front and back. | |

|

Step 5. Prepare the new brake pads by installing the rear shims from the prior step. Add some dabs of anti-squeal brake lube to the back of the shim and then spread it out to coat it. If you want, you can take time to clean up the cross spring as well. | |

|

Step 6. Install the brake pads. In order to get the pads in you will need to use two screw drivers and gently press the two pistons on each side back in. Once enough space has been made the new pads will slide in easily if they are aligned to the slot properly. Do both sides. | |

|

Step 7. Install the cross spring by setting it in place as pictured. Add some anti-squeal brake lube to the two pins and slide them in their places as shown via the image to the left (under the outer tabs as shown via the red arrows and over the center tab as shown via the orange arrow). Reinsert the locking clips as shown via the blue arrow. | |

|

Optional Step. If you want to get your rotors turned at this time you will need to remove the caliper first. On the back of the caliper, remove the two 22mm bolts and set the caliper on a bucket, hold it, or hang it with wire while you remove the rotor. DO NOT let it hang by the brake line. If you are having difficulties with the top bolt you can remove the 12mm bolt holding the brake line over the 21mm bolt as seen in the picture as well. Remove the rotor. If the rotor is stuck you can hit it a few times with a rubber mallot or you can use a tight-threaded 12mm bolt to remove it by threading it through the hole located near the studs (see indent image as reference) until the rotor pops off. Take the rotor and have it machined. When done, reinstall the rotor and then the caliper. | |

| REAR BRAKES. Rear pads are installed following the same steps above. The only difference is that the rear caliper only has one piston per side instead of two, thus, you will only need one screwdriver when pressing in the pistons.. | ||

| Brake Fluid Reservoir. When done with the steps above you need to first check the brake fluid level and ensure it is not overflowing. Reinstall the cap over the reservoir. Crank the car and depress the brakes a few times. The first time you press the pedal it will be loose until the pistons are against the pads. Afterward you will have proper brake feel. Now, check the brake fluid line make sure the brake fluid is not past the "maximum" line. If it is, remove more fluid. If it's not, make sure it's not under the "minimum" line. If it is, fill it backup up. | ||

Disclaimer: The author will not be held responsible nor held liable for any damages due to these instructions. Anyone following these directions are doing so at their own risk. This Documentation may not be distributed without the authors consent. |

||